Development of precision chemical materials to support high

integration of semiconductor devices and advanced display systems

Maleimide / Melamine Derivatives (HM3 / BPDA)

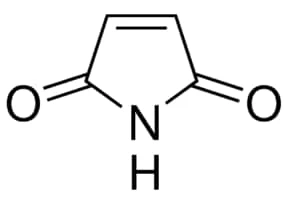

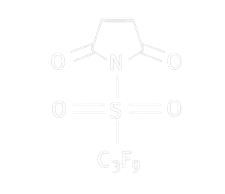

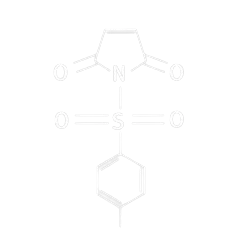

Maleimide is used as a raw material for special coating substances in displays and semiconductors. It is transparent, has high mechanical strength, and absorbs UV rays. Due to these properties, maleimide is added as a binder (adhesive) in various LCD films during the acrylic acid manufacturing process, and is also used in TSPs and organic insulating films. Therefore, products require extremely low metal content and high purity.

In semiconductor manufacturing, maleimide also plays a key role in the production of chemical amplification-type photoresists, serving as a photo acid generator (PAG) or thermal acid generator (TAG). Due to technological limitations, conventional Chinese products with insufficient thermal stability have posed challenges. Production has been difficult both domestically and internationally, resulting in supply shortages.

Our R&D-developed maleimide product line has improved thermal performance and, for the first time in the world, has achieved a purity of over 99.9%, with total metal content below 45 ppb, and is now produced in a mass-production system delivering the highest quality maleimide available.

Chemical name: Maleimide

CAS No.: 541-59-3

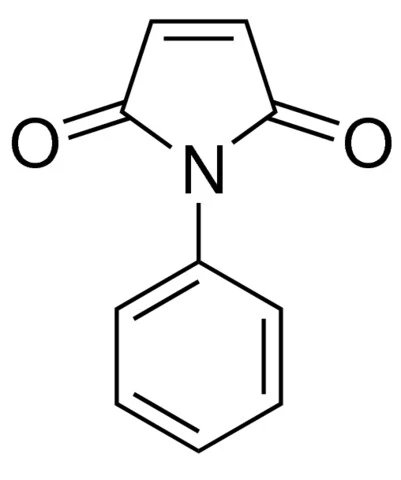

Chemical name: N-Phenylmaleimide

CAS No.: 941-69-5

Chemical name: N-Cyclohexylmaleimide

CAS No.: 1631-25-0

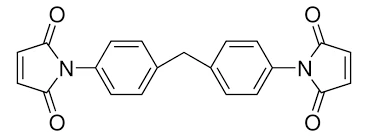

Chemical name: Bismaleimide

CAS No.: 13676-54-5

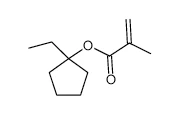

methacrylate

CAS No.: 266308-58-1

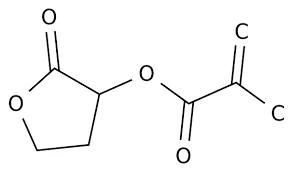

methacrylate (GBLMA)

CAS No.: 195000-66-9

Applications of Precision Chemical Materials for Semiconductors and Displays

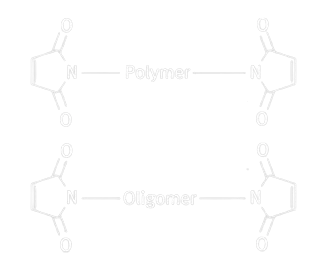

HM3, developed by our company, is a high-purity material (over 99%) with metal content below 50 ppb.

It serves as a crosslinking agent for anti-reflective coatings and negative photoresists.

The key feature of this product is that it is a formaldehyde-free crosslinking agent.

HM3, a melamine derivative, is a core substance used in construction materials such as paints, adhesives, and coatings.

Melamine adhesives are produced through a reaction between formaldehyde and melamine. These adhesives are widely used in construction materials due to their excellent performance in quick drying and maintaining strength after curing.

However, HM3 contains about 0.5–1% formaldehyde, and prolonged exposure to environments containing HM3 may release toxic substances that are known to cause Sick Building Syndrome (SBS) and may be carcinogenic.

Recently, due to the risks of formaldehyde, the use of melamine adhesives—along with urea adhesives—in building materials has decreased.

Our company was the first to develop and launch a product that reduces residual formaldehyde to below 50 ppb, effectively solving indoor environmental pollution issues and eliminating the risk of Sick Building Syndrome. In moisture-free environments, formaldehyde is not regenerated during the crosslinking process and is virtually nonexistent after curing and coating.

Major clients come from various sectors, including construction materials, footwear, automotive seats, paints, adhesives, semiconductors, and display industries.

Chemical name: Hexamethoxymethyl melamine (HMMM, HM3)

CAS no.: 3089-11-0

Key Features & Benefits Physical, Mechanical, Electrical, and Chemical properties under high-temperature conditions

High tesile strength and modulus, and also features outstanding long-term heat resistance.

Minimal content of insoluble particles (foreign material)

High degree of whiteness

Low moisture conten

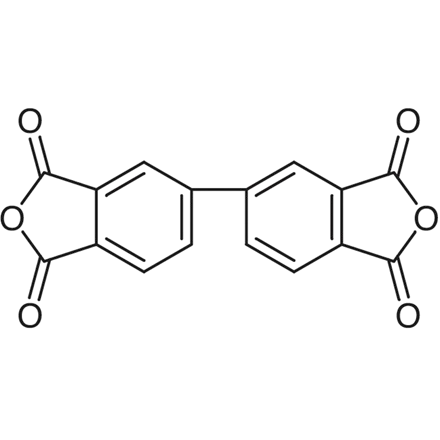

Chemical Name: 3,3',4,4'-Biphenyltetracarboxylic dianhydride

CAS No.: 2420-87-3

Specification BPDA is a raw material for the polyimide resin component of one of the super-engineering plastics.

It is used for many important information and electronic technology products such as mobile phones

and copying machines.