반도체 소자의 고집적화 및 디스플레이 기기의 정밀화학소재 개발

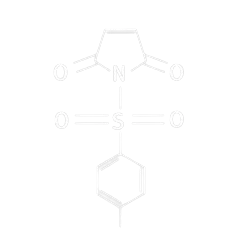

말레이미드 / 멜라민 유도체 (HM3 / BPDA)

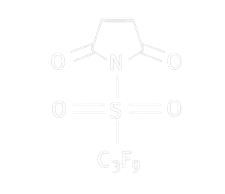

말레이미드는 디스플레이 및 반도체 등의 특수 코팅물질 원료로 사용된다. 말레이미드는 투명하고, 기계적 강도가 높으며,

UV를 흡수하는 등의 특성이 있어 아크릴산 제조 과정에서 LCD용 각종 필름에 들어가는 바인더(점착제)에 말레이미드를

첨가하거나 TSP, 유기절연막 등에 활용이 되고 있으므로 금속의 함량이 매우 낮고 순도가 높은 제품이 요구된다.

또한 반도체 제조에 있어 화학증폭형 포토레지스트의 제조에 첨가하는 광산발생제 또는 열산 발생제의 제조에 있어서도

주요 역할을 담당하는 소재이다.

현재 기술력의 한계로 기존의 열 보전성이 확보되지 않은 중국제품을 사용하는데 애로사항이 있었으며 국내외적으로

생산이 어려워 공급이 부족하였다.

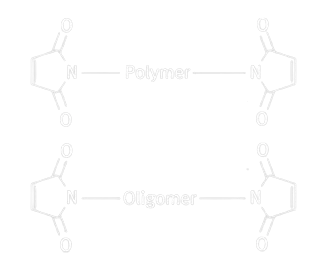

본사에서 연구개발한 말레이미드 제품군은 열특성이 우수하도록 제품 특성을 향상시켰으며 세계최초로 순도 99.9% 이상,

총 메탈함량 45 ppb 이하, 최고품질의 말레이미드의 양산체제를 갖추고 있다.

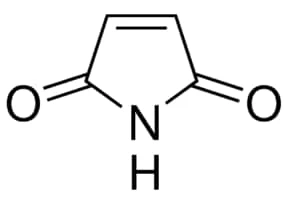

Chemical name: Maleimide

CAS No.: 541-59-3

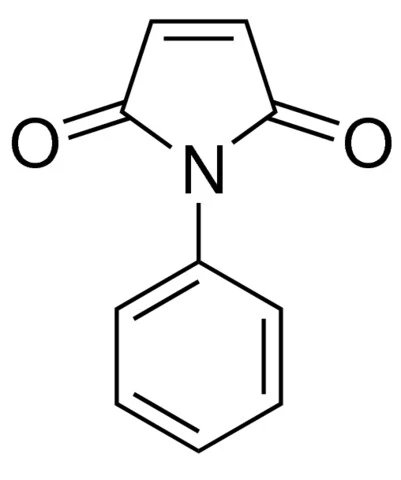

Chemical name: N-Phenylmaleimide

CAS No.: 941-69-5

Chemical name: N-Cyclohexylmaleimide

CAS No.: 1631-25-0

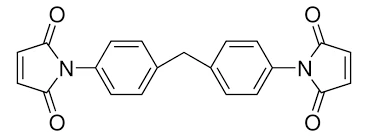

Chemical name: Bismaleimide

CAS No.: 13676-54-5

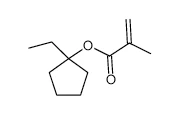

methacrylate

CAS No.: 266308-58-1

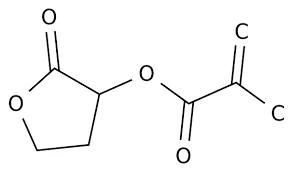

methacrylate (GBLMA)

CAS No.: 195000-66-9

반도체/디스플레이용 정밀화학소재 응용

본사에서 개발한 HM3는 순도 99% 이상, 메탈 함량이 50ppb 이하의 우수한 성적을 가진 소재이다.

반사방지막의 가교제 혹은 네카티브 포토레지스트의 가교제 역할을 한다.

제품의 가장 큰 특징은 포름알데히드를 함유하지 않은 가교제라는 점이다.

멜라민 유도체인 HM3는 건축자제에 사용되는 핵심물질로, 페인트, 접착제, 코팅제에 사용되는 중요한 소재이다.

멜라민 접착제는 포름알데히드와 멜라민의 반응으로 제조된다.

이는 건축 자재의 광범위한 분야에 사용되고 있는데, 페인트나 잉크가 빨리 마르게 하고 마른 후 강도를 지속적으로 유지 시켜주는 탁월한 성능을 가지고 있다.

그러나 HM3에는 약 0.5~1%의 포름알데히드가 함유되어 있으므로 HM3가 포함된 환경에 장시간에 걸쳐 노출이 되었을때 발생된 유독 물질은 새집증후군 및 발암의 원인이 된다.

최근에 요소접착제와 함께 멜라민 접착제도 포름알데히드의 위험성으로 인해 건축 자재에 첨가되는 물질로써 사용처가 감소하고 있다.

본사에서 처음으로 잔류 포름알데히드 수준을 50ppb 이하로 낮추어 실내 환경오염 문제가 해결된 제품을 연구 개발하여 출시 함으로써, 새집증후군으로 부터 자유로워지게 되었다.

수분이 없는 환경에서 포름알데히드는 가교반응에 과정에서 재생되지 않으므로 curing 이후와 코팅 과정 후에도 포름알데히드는 거의 존재하지 않는다.

주요 고객사는 건축자재, 운동화, 자동차시트, 페인트, 접착제, 반도체, 디스플레이 분야 등으로 다양하다.

Chemical name: Hexamethoxymethyl melamine (HMMM, HM3)

CAS no.: 3089-11-0

Key Features & Benefits Physical, Mechanical, Electrical, and Chemical properties under high-temperature conditions

High tesile strength and modulus, and also features outstanding long-term heat resistance.

Minimal content of insoluble particles (foreign material)

High degree of whiteness

Low moisture conten

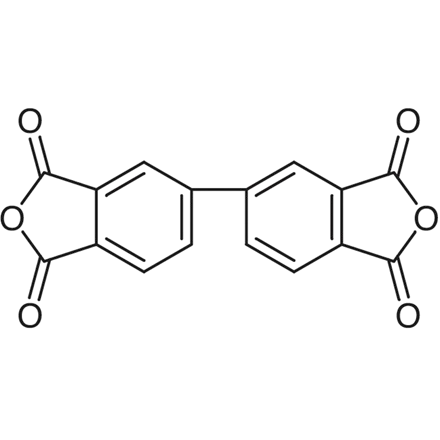

Chemical Name: 3,3',4,4'-Biphenyltetracarboxylic dianhydride

CAS No.: 2420-87-3

Specification BPDA is a raw material for the polyimide resin component of one of the super-engineering plastics.

It is used for many important information and electronic technology products such as mobile phones

and copying machines.