Market Expansion of High-Purity Graphite

Products for Semiconductors and Solar Cells

Melting point: 3,650°C

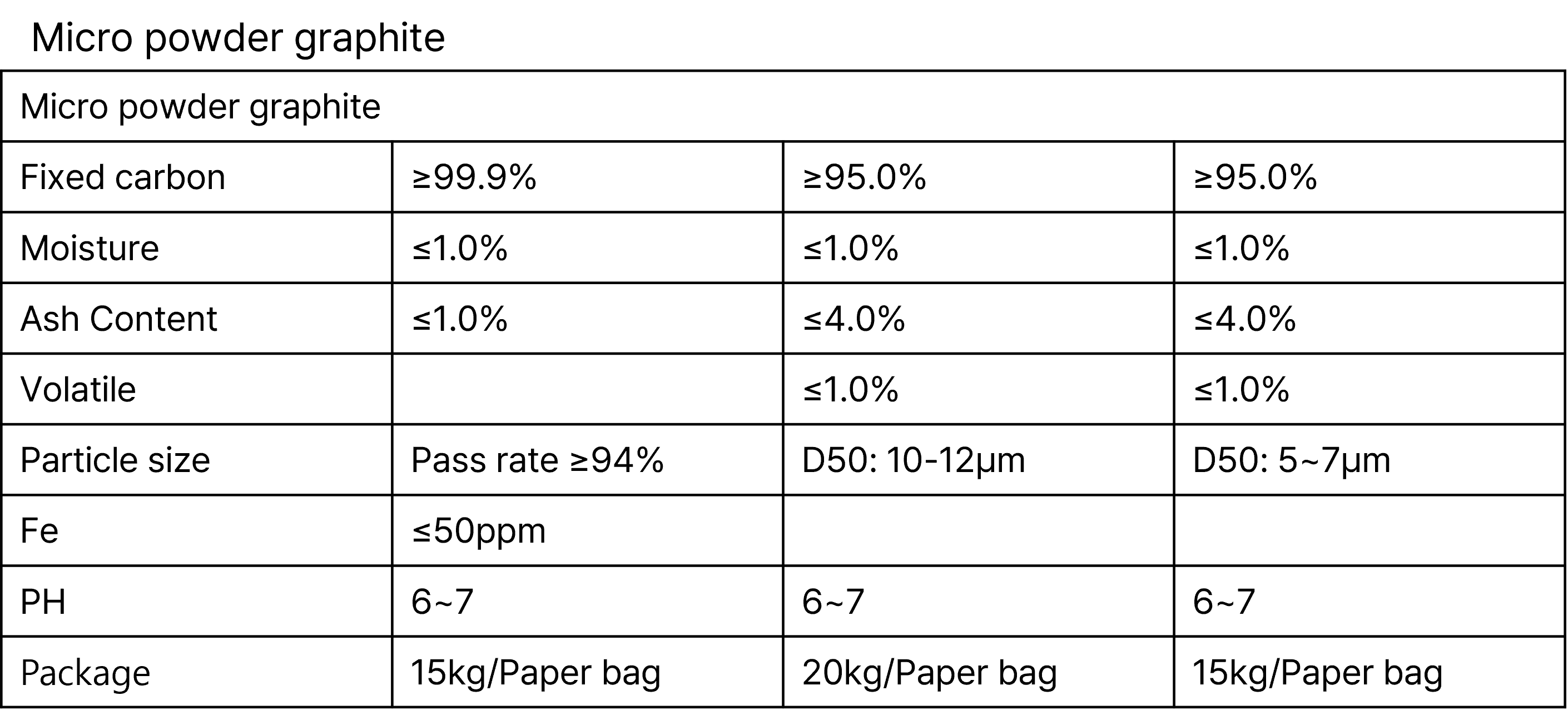

Easy to handle due to ultra-fine particles

Excellent chemical corrosion resistance

Outstanding electrical conductivity

Used as a raw material not only for anode active materials in secondary batteries, but also for graphene synthesis.

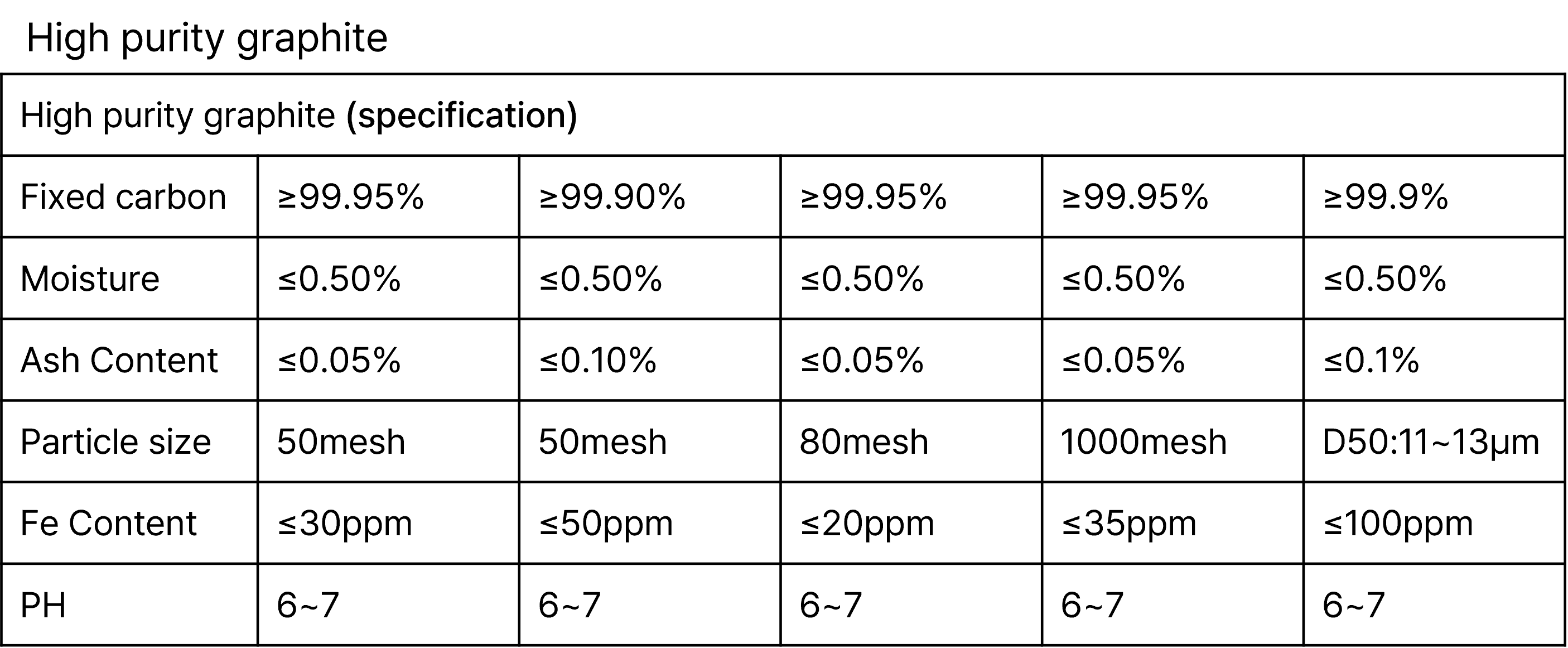

High-purity flake graphite is the main raw material for secondary battery anodes.

It is gaining attention as a raw material for graphene production.

Neopatam possesses technology for mass production of high-purity flake graphite and is preparing for overseas technology exports.

Neopatam's high-purity graphite production technology is eco-friendly and generates virtually no wastewater.

Active materials for secondary batteries are mixed with binders and solvents, then coated onto aluminum foil (for cathodes) or copper foil (for anodes). They are then pressed to increase density, forming electrodes.

Graphite, a commonly used anode material, exists in two forms: natural graphite and synthetic graphite.

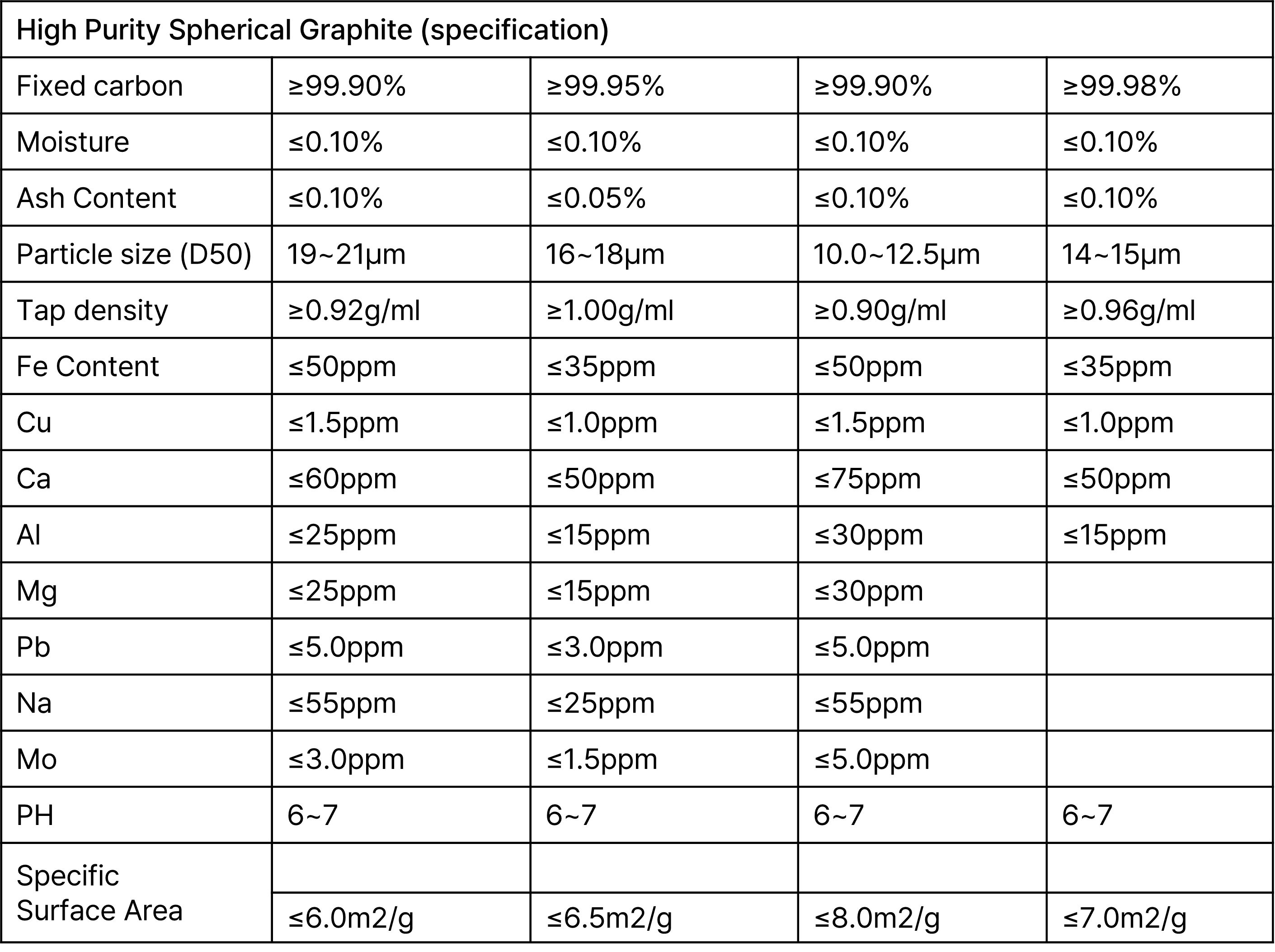

Natural graphite, with a flake-like particle shape, has low electrode density and limited battery capacity. Therefore, spherical shaping technology for natural graphite is essential.

This technology involves trimming the corners of particles and separating fine powder to obtain high-purity spherical particles.

Lithium-ion secondary batteries made using spherical graphite materials, which are ideal as anode materials, offer high capacity, high efficiency, and long lifespan, delivering excellent performance.